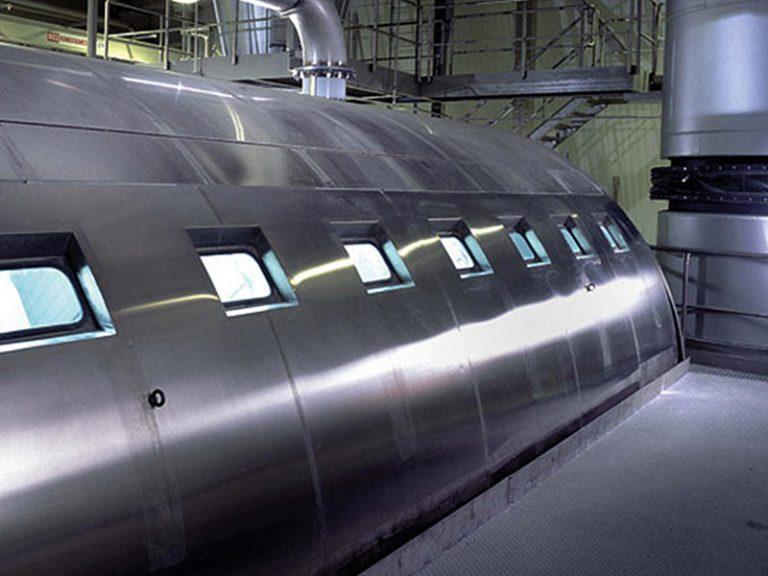

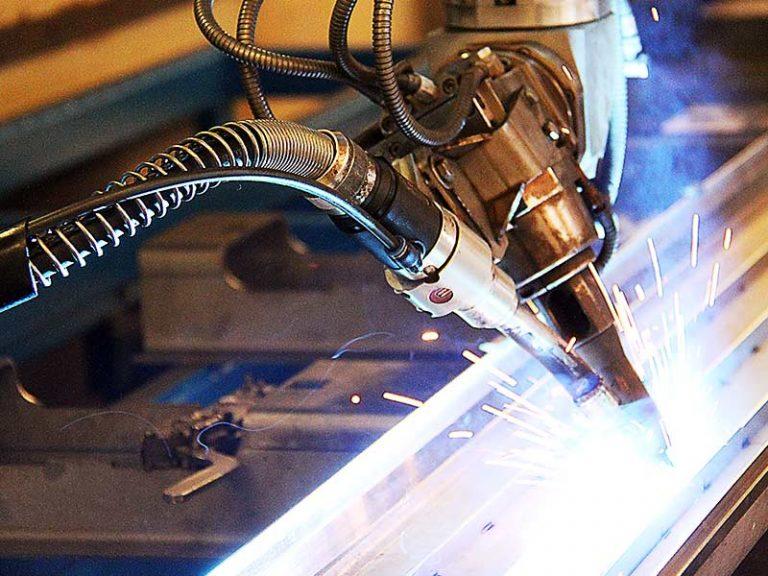

Laser welding and cutting

We are pioneers of laser welding and laser cutting in Finland. We have a robot for 3D laser welding, cutting and forming, which enables us to make new types of sheet metal structures. We can also use hybrid welding, which combines laser welding with a more traditional power source (MIG welding). A laser robot can be used to design and make advanced actuator structures and subcomponents free of production-technique limitations.