Case: HUS Meilahti hospital – Metos Oy Ab – High Metal Oy

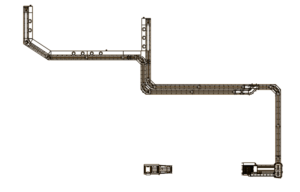

High Metal has designed and manufactured to Metos Oy Ab a hospitals personnel canteens dish return- and handling system. The system is dimensioned for 1500 dishes / hour. System was tailored to fit to existing, fully refurbished area.

Trays with dishes are returned to dishwashing room via two polycord conveyors, which are connected to one line before flight type dishwashing machines. Meal guest picks papers to integrated waste bins and places tray on conveyor.

Plates, bowls and dishes washed in racks are washed in 2 Metos WD-B flight type washing machines. First machine is equipped with wide washing belt. Ergonomic working heights are optimized for dishes washed in each machine.

Trays and cutleries are washed in a Metos WD 66CT combi machine. Cutlery is picked from tray with a magnet, and fed via de-magnetizer to conveyor which transports them to machines washing chutes. Trays are fed to their own washing line. In outfeed end washed trays are loaded automatically to two lowerators. When first lowerator is full, feeding is changed to second lowerator without stopping infeed lines in customer area.

Watch video of equipment: